Over the summer, I virtually attended the Global Fashion Summit, which is hosted in Copenhagen, Denmark. The conference is a place where new innovations, technologies and solutions are spotlighted by stakeholders in the sustainable fashion industry with hopes of proactively championing against critical environmental, social, and ethical challenges caused by the fashion industry.

During the Future of Bio-Design Materials panel, one company stood out in my mind – Modern Meadow. I was intrigued by its product innovation. I have always been fascinated by alternative materials and their ability to sustainably imitate the appearance of conventional materials. So when I heard the company’s CEO speak of their sustainable leather alternative that is both lightweight and twice as strong as traditional leather, I was all ears.

This company has pioneered an animal-free, leather-like product called INNOVERA. The product material is constructed using plant-based proteins, biopolymers, and recycled rubber. It’s made to not only look like leather, but to “replicate the look and feel of collagen found in leather.” Impressive right? The company is betting it all on INNOVERA by focusing solely on ensuring that this product is readily available globally for consumers, distributors and beyond.

Animal-free, bio-fabricated alternative leather

With the goal of driving adoption, the Modern Meadows is partnering with industry leaders in various markets across the globe. From fashion brands to luxury car brands, and even a leather goods company have elected to use INNOVERA as a sustainable anchor to produce their leather alternative products. Sustainability fashion designers Karmuel Young and Tommy Abiyo Tedji used INNOVERA in their Autumn Winter 25 collection for their Sustasia Fashion Prize submissions during Shanghai Fashion Week. The reward is given to Asian fashion industry creatives who best showcase the uniqueness, beauty and versatility of innovative sustainable materials and practices.

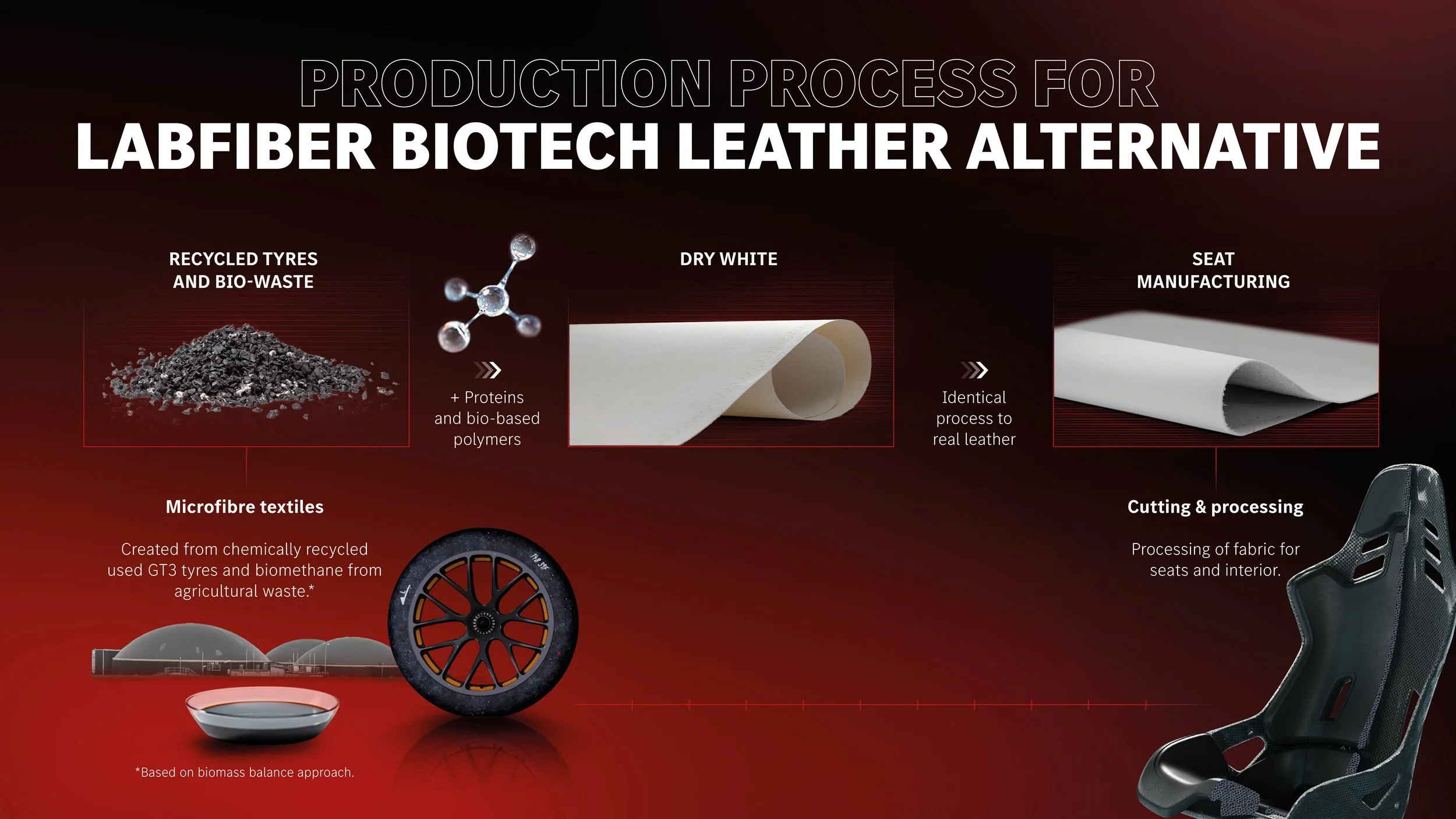

Bellroy, an Australian brand that makes backpacks, totes, luggage and other accessories, uses INNOVERA in select items as a part of a partnership offering customers alternative leather options. And more recently, Modern Meadows has announced a collection with Mercedes-Benz. The automobile giant, using INNOVERA and recycled AMG GT3 racing car tires, proteins and biopolymers, will develop a leather alternative called “LABFIBER Biotech Leather Alternative”. This leather alternative will be used as interiors in Concept AMG GT XX electric vehicles.

“Solutions often involve action, reframing, and perseverance”

After learning more about Modern Meadows and its INNOVERA alternative leather product, I realized that this company may be the solution that many sustainable brands, designers and manufacturers have been searching for. Globally, countless producers are navigating evolving standards and regulations, while others face barriers that include unclear frameworks or exorbitant costs for implementation. For example, in the EU, both the CSRD and EUDR are sustainability reporting directives created to require large companies to disclose non-financial, or ESG reports on any environmental risk they face and how their activities impact people and the environment. However, the standards have been basically sitting in “draft” with formal adoption nowhere in sight. As one can imagine the lack of clarity and delays in implementation are quite frustrating and further adds to the complication of the industry’s regulatory framework.

Mitigation

Modern Meadows shifting its focus to INNOVERA with goals to drive adoption and partner with brands across markets benefits all. This product meets varying chemical safety, labeling and trade requirements in different countries. Consumers and manufacturers interested in circular and biobased products don’t have to second guess INNOVERA’s drop-in capability when searching premier sustainable leather alternatives. There is a growing hunger for more sustainable, innovative products, and manufactures would like to navigate the barriers and unexpected costs of regulation. INNOVERA just may be the investment.

Sources:

Williamson, CEO David. Submitted Questions. 24 June 2025.